VDP-01: Metal vane demister pad.

Vane type mist eliminators, also called chevron type demister pad and droplet separators, consist of several zig-zag chevron blades with certain spacing. They are available in metal materials and high performance plastics. And the stainless steel and PP materials are the most popular types.

Comparison of Vane type mist eliminator and Wire Mesh Demister Pads

The vane (chevron) type mist eliminators supplies high separation efficiency even in the high gas or vapour velocities conditions. And they performs better in places where the small solid particles presents.

The demister pad has perfect separation performance in the moderate gas velocities.

Working Principle of Vane/Chevron Mist Eliminators

Vane mist eliminators are widely used to separate entrained liquid droplets from gas stream, which the liquid droplets are 8 μm or larger. When the gas stream passes through the chevron type mist eliminators and changes flow direction, the liquid droplets are unable to change direction as quick as the gas due to their momentum. So the liquid droplets impact on the chevron blade and then coalesce and form large droplets until drain away.

Classification of Vane/Chevron Mist Eliminators

According to the material

Vane type droplets separators can be divided into metal vane demister pad and plastic vane demister pad.

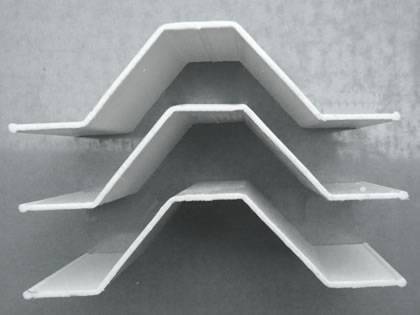

VDP-01: Metal vane demister pad.

VDP-02: Plastic vane demister pad.

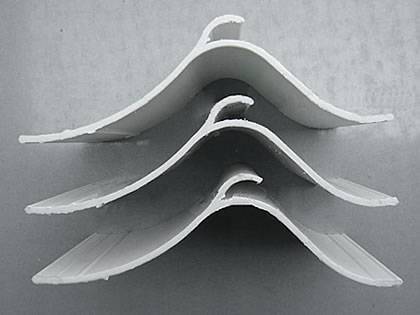

According to the blade type

The blade profile can be smooth or with hooks.

VDP-03: Smooth blade vane demister pad.

VDP-04: Hook blade vane demister pad.

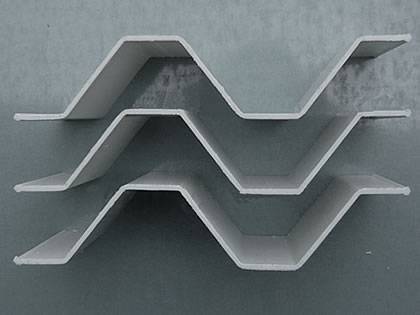

According to the passes

The vane type eliminator can be divided into two passes and three passes.

The number of passes corresponding to the number of times the gas flow change direction. More the passes, better the separating efficiency. Additional, the vane demister pad can be divided into stream line type and broken line type.

VDP-05: Stream line vane demister pad.

VDP-06: Broken line vane demister pad.

VDP-07: Two passes vane demister pad.

VDP-08: Three passes vane demister pad.

According to the shape

The vane demister pad can be made into different shapes, for example the round shape and rectangular shape. Additional, the vane demister pad can be integrated, it can also be divided into several parts for easy transporting and installing.

VDP-09: Stream line vane demister pad.

VDP-10: Broken line vane demister pad.

Specifications of vane demister pad

Features of vane demister pad

Applications of vane demister pad

Vane demister pad is widely used in various applications to separate liquid droplets from gas streams, in all applications where a contact between liquid and flowing gas, the vane demister pad can supply a good performance. Additional, tiny mist droplets can be carried away with the gas.

It is widely used in the foaming system and high liquid viscosity system in refineries, chemicals, petrochemicals, pharmaceuticals, dyes and intermediates, aromatics and other process industries.