Flame arrestor elemento diâmetro máximo

Pára-chamas São acessórios de segurança importantes em sistemas de armazenamento e transporte de tanques de petróleo e gasodutos combustíveis e desempenham um papel importante na prevenção de desastres como explosões e incêndios.

O pára-chamas divide a seção transversal de um gasoduto em várias seções com diâmetros pequenos o suficiente. Depois que uma chama passar por esses pequenos canais, ela se transformará em várias pequenas chamas e será extinta depois de se mover uma certa distância. Isso se chama "quenching". Atualmente, existem duas visões principais sobre o princípio da têmpera de chamas. Uma é que a transferência de calor é a principal razão para alcançar a resistência ao fogo, enquanto a outra é que o efeito parede tem uma grande influência na têmpera da chama.

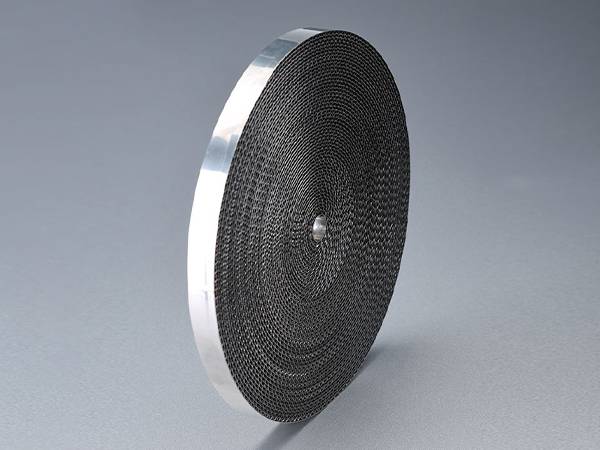

Aço inoxidável corrugado chama elemento arrestor

Instalação Flame Arrestor

O local da instalação influencia a seleção do pára-chamas. Isso porque a distância entre a fonte de ignição e o pára-chamas varia e causa a diferença na velocidade de propagação da chama, que por sua vez afeta a seleção do pára-chamas.

O pára-chamas do tanque de armazenamento é adequado apenas para instalação no tubo curto para ventilação do tanque de armazenamento. Pode ser usado separadamente ou combinando com uma válvula respiratória. No entanto, a distância entre o pára-chamas e o ponto de flashback não deve exceder 5 vezes o diâmetro do tubo selecionado. Além disso, ele só pode ser usado em ambientes onde gases inflamáveis estão presentes, mas não há chama aberta. O prendedor da chama do fedido do armazenamento pode somente impedir que as chamas com uma velocidade de não mais de 45 m/s passem completamente, assim que seu retardador de fogo não pode cumprir as exigências do prendedor da chama do encanamento. Portanto, o pára-chamas do tanque de armazenamento não pode ser usado como alternativa ao pára-chamas do gasoduto.

Quando um gasoduto de fornecimento de gás combustível é conectado a um queimador sem outras instalações anti-backfire, um pára-chamas deve ser instalado.

| Diâmetro nominal do tubo (DN) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Instalação mínima distância (L/m) | 0,5 | 1 | 1,5 | 2 | 3 | 4 | 6 | 8 | 10 | 10 | 10 | 10 |

Notas:

Design Flame Arrestor

Notas:

Flame arrestor elemento diâmetro máximo

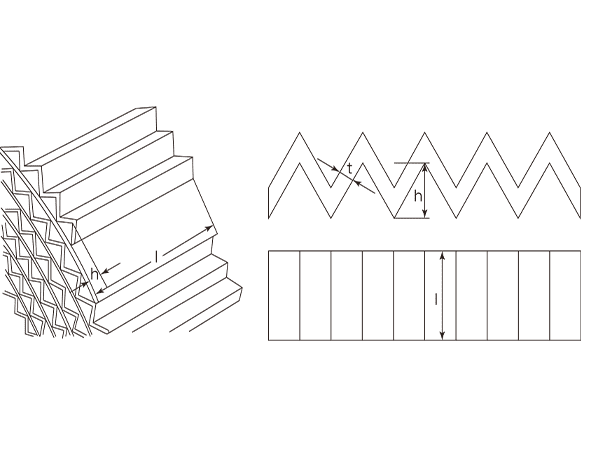

Estrutura do elemento do pára-chamas

Chama elemento prendedor espessura inspeção

Chama elemento prendedor regular triângulo altura inspeção

Chama elemento pára-chamas

Elementos corta-chamas vistos de diferentes ângulos