PP

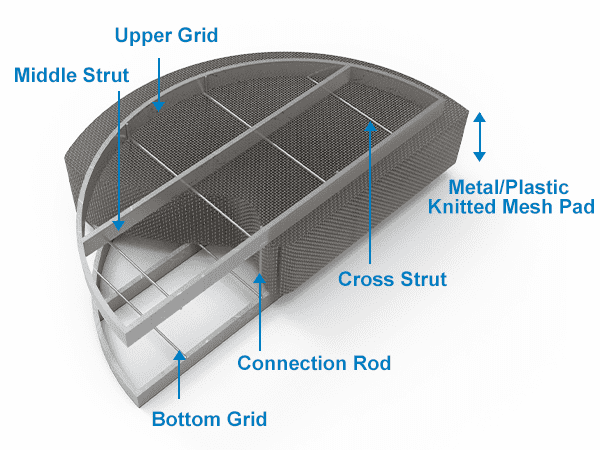

Névoa eliminador Consiste em grade superior, suporte médio, grade inferior, haste de conexão, suporte transversal e malha de metal/plástico.

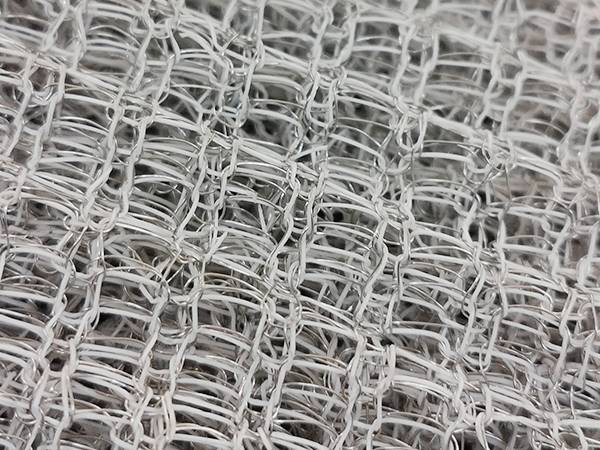

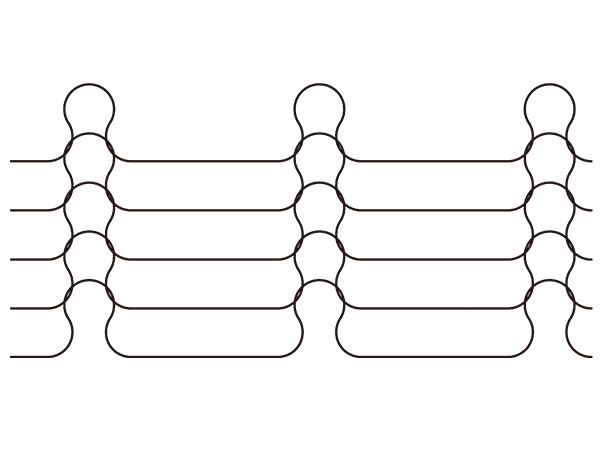

Metal/plástico malha pad é um tipo de filtro de gás líquido metal/plástico malha pad feito de metal ou fios não metálicos.

PP

Aço inoxidável

PE + aço inoxidável

| Tipo | Volume (kg/m3) | Superfície (m2/M3) | Vacuidade ɛ |

|---|---|---|---|

| SP | 168 | 529,6 | 0,9788 |

| DP | 186 | 625,5 | 0,9765 |

| HP | 128 | 403,5 | 0,9839 |

| RH | 134 | 291,6 | 0,9832 |

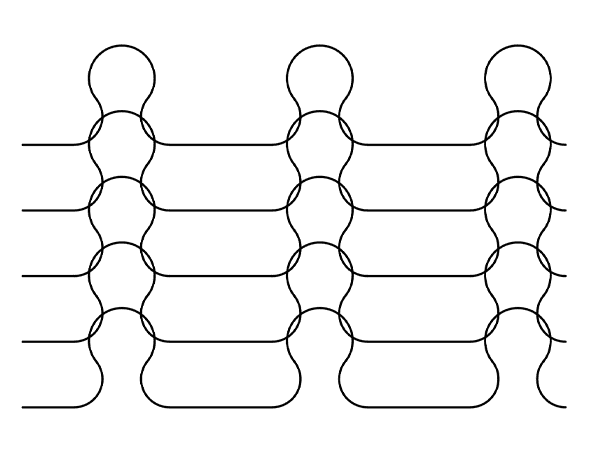

SP gás-líquido filtro metal/plástico malha pad

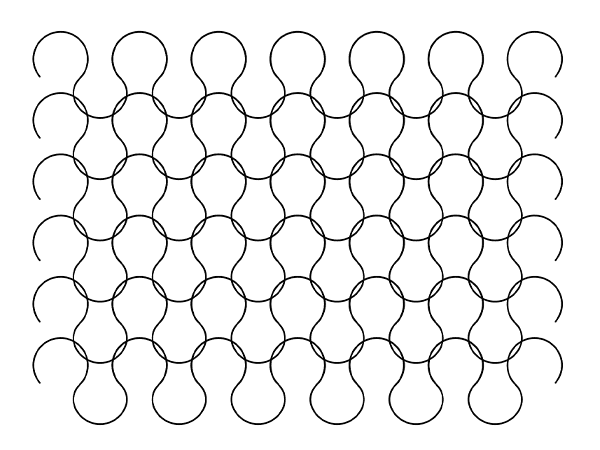

DP gás-líquido filtro metal/plástico malha pad

HR/HP filtro gás-líquido metal/plástico malha pad

| Tamanho do fio (mm) | Malha Largura Tolerância (mm) | Densidade (kg/m3) | Superfície (m2/M3) | Vazamento ɛ | ||

|---|---|---|---|---|---|---|

| Fio liso | Fio redondo | ± 20 | 150 | Fio liso | Fio redondo | 0,981 |

| 0,1 × 0,4 | 0,23 | 475 | 320 | |||

| Nota: Cada tapete de malha de 100mm é composto por 28 camadas de malha de arame. | ||||||

| Tamanho do fio (mm) | Malha Largura Tolerância (mm) | Densidade (kg/m3) | Superfície (m2/M3) | Vacuidade ɛ | ||

|---|---|---|---|---|---|---|

| Fio liso | Fio redondo | ± 20 | 182 | Fio liso | Fio redondo | 0,977 |

| 0,1 × 0,3 | 0,19 | 626 | 484 | |||

| Nota: Cada esteira grossa da malha 100mm é composta de 32 camadas de rede de arame. | ||||||

| Tamanho do fio (mm) | Malha Largura Tolerância (mm) | Densidade (kg/m3) | Superfície (m2/M3) | Vazamento ɛ | ||

|---|---|---|---|---|---|---|

| Fio liso | Fio redondo | ± 20 | 98 | Fio liso | Fio redondo | 0,9875 |

| 0,1 × 0,4 | 0,23 | 313 | 217 | |||

| Nota: Cada tapete de malha de 100mm é composto por 28 camadas de malha de arame. | ||||||

Névoa Eliminador – Grade

A grade do eliminador de névoa é frequentemente feita de aço inoxidável ou PP. Ao usar o eliminador de névoa, se a área da bandeja na torre que suporta o eliminador de névoa for grande, a grade deve ser usada. Porque a almofada de malha é mais macia e fácil de cair do espaço maior da bandeja sem grade.

Grades do aço inoxidável

Grades PP

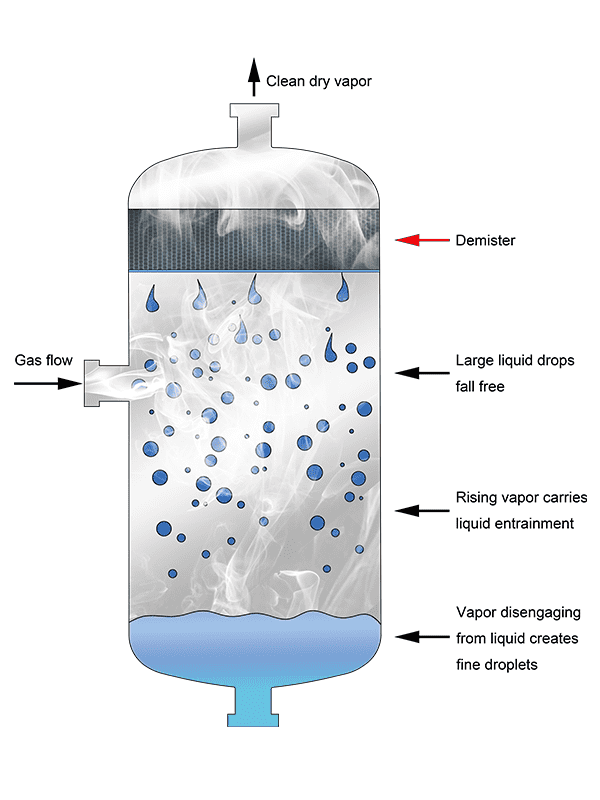

Quando o gás com névoa sobe a uma velocidade constante e passa através da almofada de malha de metal/plástico, a névoa ascendente colide com o filamento da malha e é anexada ao filamento da superfície devido ao efeito de inércia. A névoa na superfície do filamento se difunde ainda mais, e a gravidade da própria névoa se instala para formar grandes gotículas. As gotículas maiores fluem em direção aos filamentos na interseção dos dois fios. Devido à molhabilidade do filamento, a tensão superficial do líquido e a ação capilar do filamento fazem com que as gotículas cresçam cada vez maiores até que sua própria gravidade exceda a força combinada da flutuabilidade ascendente do gás e da tensão superficial do líquido, Separando a gota e fluindo para o equipamento a jusante da embarcação. Desde que a velocidade do gás e outras condições sejam selecionadas corretamente, depois que o gás passa pelo eliminador de névoa, a eficiência de eliminação de névoa pode atingir mais de 97% e pode até atingir o objetivo de remover completamente a névoa.

Princípio do funcionamento do eliminador Névoa

Névoa eliminador funcionamento princípio fluxograma

Quando a manutenção é necessária?

Como para manter?

O método de manutenção é enxaguar com água limpa, mas deve-se notar que, para evitar a produção de ácidos diluídos na almofada de malha, afetando a vida útil, a almofada de malha do eliminador de névoa deve ser seca após o enxágue (em seu estado natural, a secagem também pode ser feita). Instale a almofada de malha na torre antes de iniciar a operação.

Se você está interessado, por favor Contacte-nos