PP

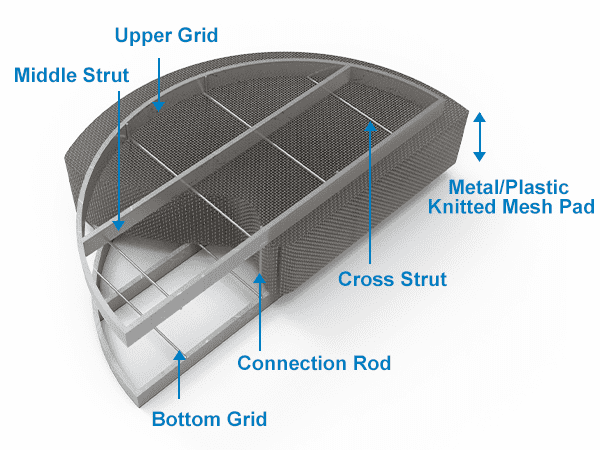

Mist eliminator consists of upper grid, middle strut, bottom grid, connection rod, cross strut, and metal/plastic knitted mesh pad.

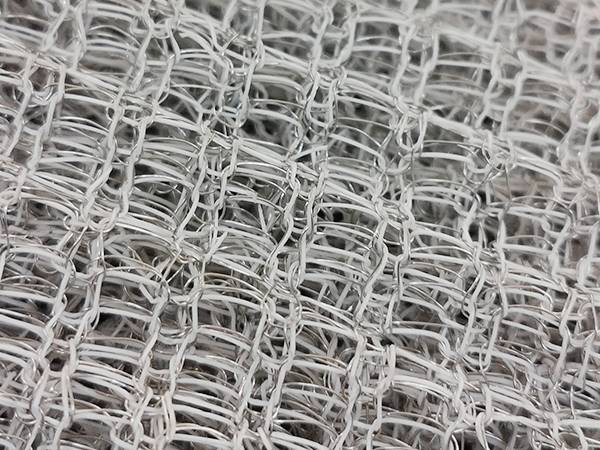

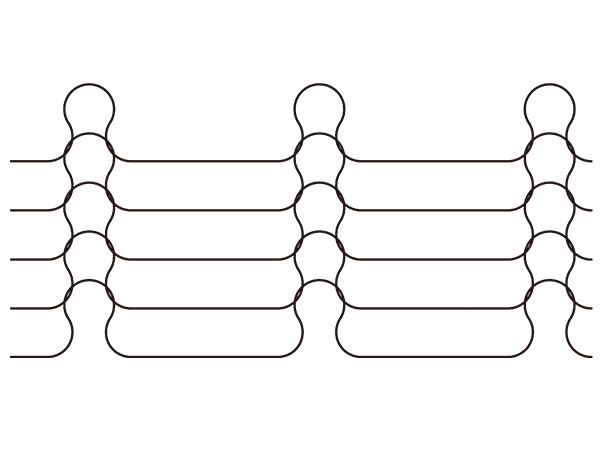

Metal/Plastic knitted mesh pad is a kind of gas-liquid filter metal/plastic knitted mesh pad made of metal or non-metal wires.

PP

Stainless steel

PE + stainless steel

| Type | Volume (kg/m3) | Surface Area (m2/m3) | Voidage ɛ |

|---|---|---|---|

| SP | 168 | 529.6 | 0.9788 |

| DP | 186 | 625.5 | 0.9765 |

| HP | 128 | 403.5 | 0.9839 |

| HR | 134 | 291.6 | 0.9832 |

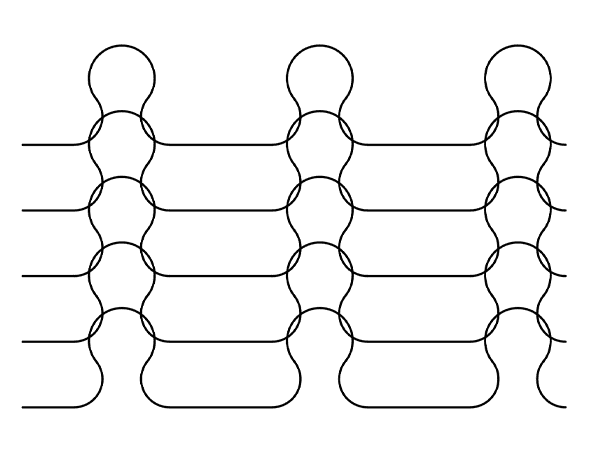

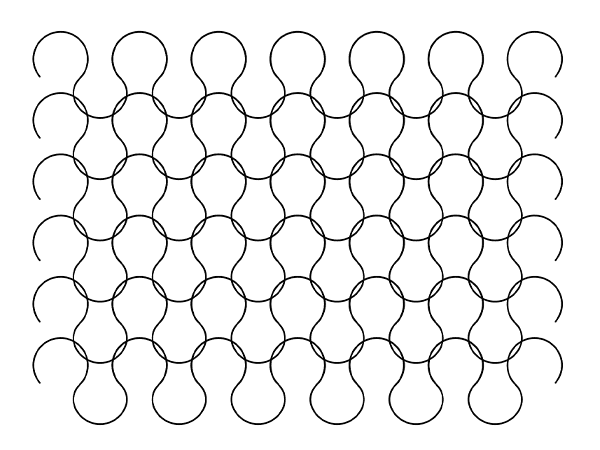

SP gas-liquid filter metal/plastic knitted mesh pad

DP gas-liquid filter metal/plastic knitted mesh pad

HR/HP gas-liquid filter metal/plastic knitted mesh pad

| Wire Size (mm) | Mesh Width Tolerance (mm) | Density (kg/m3) | Surface Area (m2/m3) | Voidage ɛ | ||

|---|---|---|---|---|---|---|

| Flat Wire | Round Wire | ± 20 | 150 | Flat Wire | Round Wire | 0.981 |

| 0.1 × 0.4 | 0.23 | 475 | 320 | |||

| Note: Every 100 mm thick mesh mat is made up of 28 layers of wire mesh. | ||||||

| Wire Size (mm) | Mesh Width Tolerance (mm) | Density (kg/m3) | Surface Area (m2/m3) | Voidage ɛ | ||

|---|---|---|---|---|---|---|

| Flat Wire | Round Wire | ± 20 | 182 | Flat Wire | Round Wire | 0.977 |

| 0.1 × 0.3 | 0.19 | 626 | 484 | |||

| Note: Every 100 mm thick mesh mat is made up of 32 layers of wire mesh. | ||||||

| Wire Size (mm) | Mesh Width Tolerance (mm) | Density (kg/m3) | Surface Area (m2/m3) | Voidage ɛ | ||

|---|---|---|---|---|---|---|

| Flat Wire | Round Wire | ± 20 | 98 | Flat Wire | Round Wire | 0.9875 |

| 0.1 × 0.4 | 0.23 | 313 | 217 | |||

| Note: Every 100 mm thick mesh mat is made up of 28 layers of wire mesh. | ||||||

Mist Eliminator – Grid

The grid of the mist eliminator is often made of stainless steel or PP. When using the mist eliminator, if the area of the tray in the tower supporting the mist eliminator is large, the grid should be used. Because the mesh pad is softer and easy to fall off from the larger gap of the tray without grid.

Stainless steel grids

PP grids

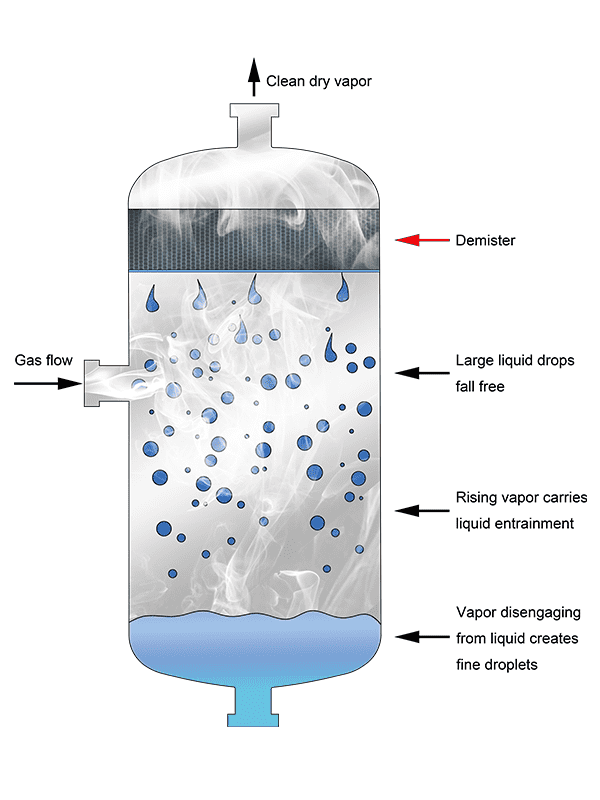

When the gas with mist rises at a constant speed and passes through the metal/plastic knitted mesh pad, the rising mist collides with the mesh filament and is attached to the surface filament due to the inertia effect. The mist on the surface of the filament diffuses further, and the gravity of the mist itself settles to form large droplets. The larger droplets flow towards the filaments at the intersection of the two wires. Due to the wettability of the filament, the surface tension of the liquid and the capillary action of the filament make the droplets grow larger and larger until their own gravity exceeds the combined force of the rising buoyancy of the gas and the surface tension of the liquid, separating the drop and flowing into the vessel's downstream equipment. As long as the gas speed and other conditions are properly selected, after the gas passes through the mist eliminator, the mist elimination efficiency can reach more than 97%, and can even achieve the purpose of completely removing the mist.

Mist eliminator working principle

Mist eliminator working principle flow chart

When Maintenance Is Required?

How to maintain?

The maintenance method is to rinse with clean water, but it should be noted that in order to avoid the production of dilute acids on the mesh pad, affecting the service life, the mesh pad of the mist eliminator must be dried after rinsing (in its natural state, drying can also be done). Install the mesh pad in the tower before starting operation.

If you are interested, please contact us